Metallic Pipes & Fittings

ARBON, GALVANIZED STEEL, ASME, ANSI TANDARDS. CARBON STEEL, STAINLESS STEEL, EXOTIC MATERIAL

DUCTLIE RION - For conveyance of fluids and solid particles

Pipeline mostly used to convey water, sewage, and other liquid or solid materials from the source to the distribution or facility.

Standards: AWWA C200, ANSI/AWWA C153/A21.53 and ANSI/AWWA C111/A21.11, ISO 2531, EN 545 (potable water) and EN 598 (sewage) Most common connections: Spigot and socket, Flanges, Restrained Joint, Mechanical Joint

CARBON STEEL - For pressure &temperature services

It is utilized to carry gases, vapors, and high-temperature mixtures from one location to another.

Standard: ASTM A53. ASTM A106, ASME B31.1. B31.3. ASTM A234, ASTM A860, ASME B16.5, API5L. API6A etc.

Most common connections: But Welding, Socket Welding, Threads, Flanges, Grooved

STANILESS STEEL - For lower temperatures, corrosion and sanitary services

The benefits of a corrosion resistant metal when it comes to pipes should be abundantly clear. That’s why stainless steel is a common choice for piping applications.

Stainless steel pipe is primarily used in piping systems for the transport of fluids or gases

In addition to being resistant to corrosion, stainless steel has other properties that make ti an excellent choice for sanitary services such as Bio-Pharma or Food&Beverage.

Industrial Standards:

ASTM A312, ASTM A358, ASTM A249/269, A403, A S T A813/A813M, ASTM A182, ASME B16.5, ASTM A554, ANSI B16.11, ISO 4144, ISO 2999

Most common connections: Butt Welding, Socket Welding, Threads, Flanges, Grooved

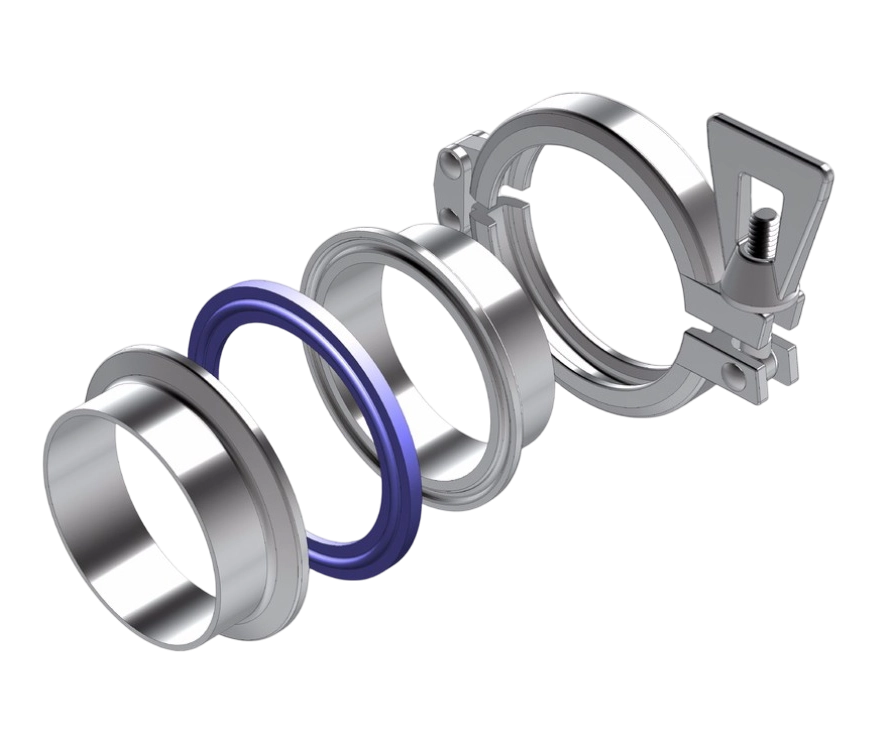

Sanitary Standards:

ASTM A270, 3A Standards, DIN 11850, DIN 11851, ISO 2853, SMS- 1145, AS1528, ISO-2582, DIN 32676, ASME-BPE Most common connections: Butt Welding, Socket Welding, Threads, Flanges, Grooved

CASING (OCTG)

Oil country tubular goods (OCT) is a family of seamless rolled products consisting of drill pipe, casing and tubing subjected to loading conditions according to their specific application:

Dril pipe si heavy seamless tube that rotates the drill bit and circulate drilling fluids. Pipe segments 30 ft long are coupled with tool joints.

Dril pipe si simultaneously subjected to high torque by drilling fluid, axial tension by its dead weight, and internal pressure by purging of drilling fluid.

Additionally, alternating bending loads due to non – vertical or deflected drilling may be superimposed on this basic loading patterns.

Casing pipelines the borehole. It is subject to axial tension byits dead weight, internal pressure by fuid purging, and external presion by surrounding rock formations. Casing si particulay exposed to axial tension and internal pressure by the pumped oil or gas emulsion.

Tubing si pipe through witch the oil or gas si transported from the wellbore. Tubing segments are generally arround 30 and 40 ft long with a threaded conecctiononeachend

STANDARDS GRADES: H-40, J-55, K-55, N-80, L-80, C-90, T-95, P-110, Q-125

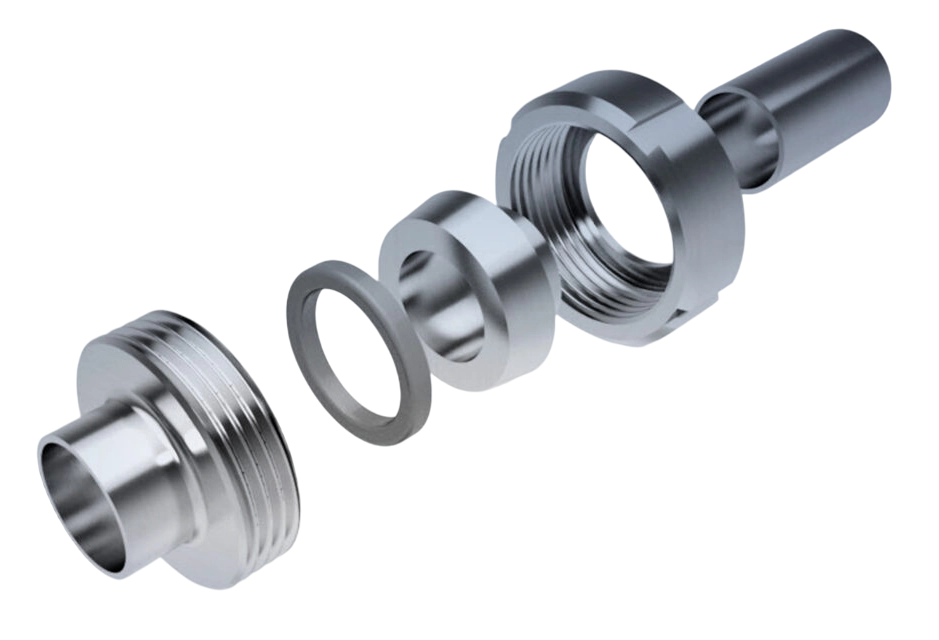

CASING ACCESORIES